Thomas Turner

Trade Member

- Joined

- Mar 22, 2017

- Messages

- 15,495

- Reaction score

- 81

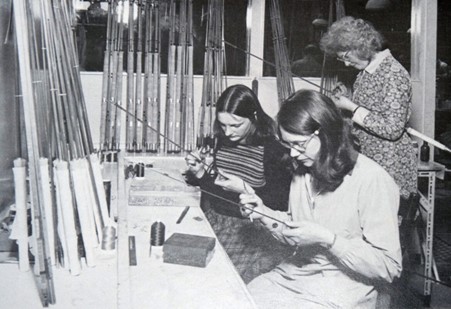

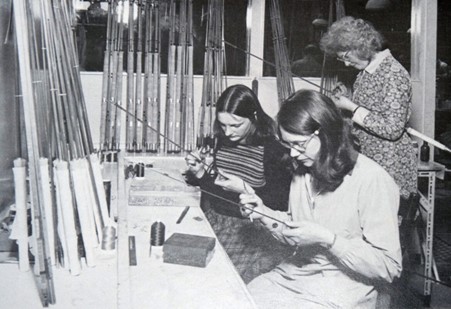

The Impregnated split cane rods above are all hand built by the craftsman. This collection of fourteen Sharpe’s, mint to brand new rods, had to be bought.

The previous owner, a lifelong angler, purchased these from the Sharpe’s shop in Aberdeen prior to its closure. He fished a couple of rods perhaps once or twice, the remaining twelve he stored correctly, never to be fished. Sadly, having passed away and with the family now moving abroad it was time to release these treasures so they can do the job they were designed to. Fishing!

What struck me was the slight colour differences between the rod models. Could this be a trait of the length or line rating? No, it’s a little more involved.

Impregnation is simply a process that fills the tube-like fibres of cane and the minute gaps between those fibres with a special resin.

This is achieved by a series of immersions at varying temperatures in resin baths. The process gives the rod more power flexing in one solid structure. The cane becomes 100% waterproof and impervious to climatic extremes. It requires no varnishing with the cane being buffed to a low satin finish, eliminating flash. In short, as the cane is a natural material all fibres are different in the level of absorption, the more resin that is impregnated the darker the cane appears.

The iconic Sharpe’s spliced joint rods are still popular today despite modern carbons and Kevlar models. Strangely the longer the rod the more popular it is. The 15’ 3-piece salmon fly is a must have for anglers on the big rivers of Scotland, Ireland and Norway. The spliced joints look odd, but they are there for a reason. Because of the solid structure, the spliced joints are waterproof eliminating the flat spot a ferrule creates. Do I hear you say “Parabolic Curve”? Where possible try to buy a rod with the wooden tapered ferrule pegs. These protect the finished ends of the tapered joints preventing chips and ultimately a split. We have seen wooden replacement pegs and they work too.

The hand-making process of a rod is complex. From cane choice splitting, removing the inner core, shaping, belt sanding etc. Post-war tapering machines removed any human error in the gluing process which was extremely difficult to achieve uniformly on all six sections. The only varnish on a Sharpe’s impregnated rod is applied at the end of the process to the silk whippings and ferrules. A story is recorded where an angler lost his rod overboard whilst lake fishing. One year later a scuba diver recovered the same rod. The cork handle had perished but the rod cane remained 100% intact, still waterproof and arrow straight.

These rods will all be listed shortly. From the Featherweight 8’6” model, right though the 9, 10, 11’ range up to the spliced salmon examples. Also, just one 9’ spinning rod which is brand new came with the bundle. It is crying out to be fished. Having done its time in storage it now needs to live again to catch a salmon, a pike, or even a carp for good measure.

If you have anything similar you would like to sell, or have valued, then please get in touch! 01782 698787 / 07548 871985 or email john@thomasturner.com. Let’s talk tackle!

The post J S Sharpes of Aberdeen impregnated rods appeared first on Thomas Turner Fishing Antiques.

Continue reading...

The previous owner, a lifelong angler, purchased these from the Sharpe’s shop in Aberdeen prior to its closure. He fished a couple of rods perhaps once or twice, the remaining twelve he stored correctly, never to be fished. Sadly, having passed away and with the family now moving abroad it was time to release these treasures so they can do the job they were designed to. Fishing!

What struck me was the slight colour differences between the rod models. Could this be a trait of the length or line rating? No, it’s a little more involved.

Impregnation is simply a process that fills the tube-like fibres of cane and the minute gaps between those fibres with a special resin.

This is achieved by a series of immersions at varying temperatures in resin baths. The process gives the rod more power flexing in one solid structure. The cane becomes 100% waterproof and impervious to climatic extremes. It requires no varnishing with the cane being buffed to a low satin finish, eliminating flash. In short, as the cane is a natural material all fibres are different in the level of absorption, the more resin that is impregnated the darker the cane appears.

The iconic Sharpe’s spliced joint rods are still popular today despite modern carbons and Kevlar models. Strangely the longer the rod the more popular it is. The 15’ 3-piece salmon fly is a must have for anglers on the big rivers of Scotland, Ireland and Norway. The spliced joints look odd, but they are there for a reason. Because of the solid structure, the spliced joints are waterproof eliminating the flat spot a ferrule creates. Do I hear you say “Parabolic Curve”? Where possible try to buy a rod with the wooden tapered ferrule pegs. These protect the finished ends of the tapered joints preventing chips and ultimately a split. We have seen wooden replacement pegs and they work too.

The hand-making process of a rod is complex. From cane choice splitting, removing the inner core, shaping, belt sanding etc. Post-war tapering machines removed any human error in the gluing process which was extremely difficult to achieve uniformly on all six sections. The only varnish on a Sharpe’s impregnated rod is applied at the end of the process to the silk whippings and ferrules. A story is recorded where an angler lost his rod overboard whilst lake fishing. One year later a scuba diver recovered the same rod. The cork handle had perished but the rod cane remained 100% intact, still waterproof and arrow straight.

These rods will all be listed shortly. From the Featherweight 8’6” model, right though the 9, 10, 11’ range up to the spliced salmon examples. Also, just one 9’ spinning rod which is brand new came with the bundle. It is crying out to be fished. Having done its time in storage it now needs to live again to catch a salmon, a pike, or even a carp for good measure.

If you have anything similar you would like to sell, or have valued, then please get in touch! 01782 698787 / 07548 871985 or email john@thomasturner.com. Let’s talk tackle!

The post J S Sharpes of Aberdeen impregnated rods appeared first on Thomas Turner Fishing Antiques.

Continue reading...